Have you ever wondered why some adhesives stick instantly while others struggle? Or why a bond perfectly suitable for a lightweight component fails when subjected to vibration or temperature changes? What truly differentiates an adhesive that performs flawlessly on metal from one that can reliably bond challenging plastics like polypropylene? For product designers, engineers, and manufacturing professionals, navigating the vast landscape of adhesive solutions can feel like guesswork, often leading to costly failures, rework, and compromised product integrity. By delving into the science of surface energy and applied forces, this guide will equip you to precisely select the optimal 3M™ adhesive, ensuring unwavering bond performance and lasting reliability for your most demanding applications.

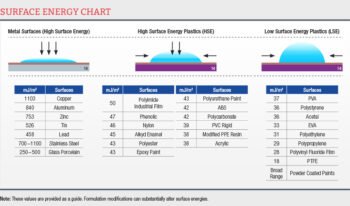

Optimal adhesive or tape selection hinges primarily on three foundational principles. First and foremost is Substrate Compatibility and Surface Energy, which dictates an adhesive’s ability to “wet out” and bond effectively with the materials; high surface energy (HSE) substrates (e.g., metals, glass) bond more readily than low surface energy (LSE) materials (e.g., polypropylenes, powder coatings), often requiring specialized adhesives or surface treatments. Secondly, the Load Profile is critical, defining the types and magnitude of forces (tensile, shear, peel, cleavage, impact, dynamic) the bond must continuously withstand, as different adhesives excel under specific stress modes. Thirdly, Environmental Conditions are paramount, covering the operational temperature range, humidity, UV exposure, and chemical resistance necessary for long-term bond integrity.

Beyond these core determinants, a robust selection process also considers the practicalities of bond aesthetics (e.g., invisible bond lines), the requirements for gap filling or sealing, the need to accommodate dissimilar material bonding (and their differential thermal expansion), and the desired flexibility or rigidity of the final joint. Operational factors such as application method, cure/fixture times, and the feasibility of surface preparation within manufacturing workflows are also vital for successful implementation and product quality.

Leveraging the foundational understanding of surface energy and load requirements, 3M offers an unparalleled breadth of adhesive technologies, each meticulously engineered to deliver optimal performance for specific application challenges. This portfolio provides precise solutions that go beyond generic sticking, ensuring robust and reliable bonds for even the most demanding designs and manufacturing processes. To navigate this advanced range, here’s a summary of key 3M™ adhesive families and their primary strengths:

3M™ Adhesive Family | Key Strengths & Primary Applications | Ideal For… |

3M™ VHB™ Tapes | Viscoelastic acrylic foam. Excellent for stress distribution, vibration damping, and accommodating thermal expansion. Provides high shear, tensile, and peel strength. Replaces mechanical fasteners. | Permanent, structural bonding of HSE & LSE substrates (specialized versions), translucent materials (clear VHB), dynamic loads, sealing, eliminating visible fasteners, bonding dissimilar materials. |

3M™ Scotch-Weld™ Structural Adhesives (Epoxies, Urethanes, Acrylics) | High ultimate strength, rigidity, and environmental resistance. Chemically cures for a very strong, durable bond. Available in various work lives and cure times. | Critical structural bonds (metals, composites), extreme load requirements, high temperature/chemical exposure, large area bonding, gap filling where rigidity is needed. |

3M™ Scotch-Weld™ Cyanoacrylate Adhesives (CAs) | Very fast curing (seconds), high tensile strength. Bonds many plastics, rubbers, and metals. Available in various viscosities (thin to gap-filling). | Rapid assembly, small bond areas, quick fixturing, bonding of rubber, plastics, and metal where speed is paramount. |

3M™ Pressure Sensitive Adhesives (PSAs) (Transfer & Double-Sided Tapes) | Instant adhesion (no cure time), high initial tack, versatile for many materials. Available in various thicknesses and adhesive types for different performance profiles. | General mounting, laminating, attaching trim/gaskets, light-duty bonds, applications requiring immediate handling strength. |

3M™ Adhesion Promoters (Primers) | Chemical treatments to prepare low surface energy (LSE) substrates (e.g., PP, PE, powder coats) for improved adhesion with other 3M™ adhesives. | Significantly enhancing bond strength and durability on challenging LSE plastics or treated surfaces where direct bonding is difficult. |

3M™ Urethane Adhesives/Sealants | Flexible, tough, excellent sealing properties, good vibration damping. Strong adhesion to many substrates, especially metals and plastics, with good environmental resistance. | Flexible bonds, sealing (especially against moisture/weather), bonding dissimilar materials that move, vibration damping, automotive and construction applications. |

3M™ LSE Liquid Acrylic Adhesives | Specifically formulated to bond low surface energy plastics directly, often without primers. Good for certain oily metals as well. | Direct bonding of polypropylene, polyethylene, and other difficult plastics in applications requiring liquid adhesive strength without extensive surface preparation. |

This diversified range ensures that 3M can provide a precision-engineered adhesive solution, matching the unique demands of each application’s surface energy, load profile, and environmental stressors.

Navigating 3M’s advanced adhesive portfolio requires a systematic approach that synthesizes your understanding of surface energy, load requirements, and application specifics. Moving beyond trial-and-error, a structured selection process ensures that the chosen solution is not only effective but also optimized for performance and manufacturing efficiency. Let’s walk through a hypothetical scenario:

An engineering team is tasked with developing an optimal bonding solution for the next generation of high-end outdoor LED display modules destined for commercial signage across India’s diverse climatic zones. The core bonding requirement is the robust attachment of a powder-coated aluminum frame to a transparent acrylic panel that functions as the protective front for the sensitive LED components. The solution must ensure long-term reliability, aesthetic appeal, and resistance to harsh environmental conditions.

Here’s how a systematic 3M adhesive selection process would unfold:

- Identify Substrates with Precision: Clearly define each material. The powder-coated aluminum presents an LSE surface despite the underlying metal. The acrylic is an HSE plastic. Note the dissimilarity (metal to plastic) which demands accommodation for differential thermal expansion. Surfaces require standard cleaning.

- Define Load Profile & Performance Expectations: The bond faces significant shear (wind, dead weight), moderate tensile (wind suction), and critical resistance to peel/cleavage. Dynamic loads (wind gusts, vibration) are also present. Environmentally, extreme temperature cycling (-10°C to +60°C), high UV exposure, and moisture/humidity (monsoons) are critical. The bond must be an invisible environmental seal with a 5-7 year service life.

- Consider Application & Manufacturing Logistics: Modular production requires quick, clean assembly with instant tack and minimal clamping. A consistent, thin bond line for aesthetics and sealing. A tape-based solution is preferred for ease of application. Room-temperature handling strength is needed, avoiding special curing equipment. Strict adherence to safety protocols is required.

- Consult 3M™ Resources & Select Potential Solutions: The combination of LSE bonding, dynamic load management, extreme environmental resistance, and invisible aesthetics strongly points to 3M™ VHB™ Tapes. Specifically, an LSE-bonding 3M™ VHB™ Tape (e.g., 5925 or 4943F series) is ideal for direct powder coat adhesion.

- Test and Validate: Essential for critical applications. Conduct lab tests for shear, peel, and tensile strength. Perform accelerated environmental testing (temperature cycling, humidity, UV) on prototypes to confirm long-term durability and seal integrity. Simulate wind load and vibration to ensure structural performance.

By following this systematic process, the engineering team can confidently select a 3M™ VHB™ Tape (e.g., a specific LSE-bonding series) as the optimal solution. This ensures the LED display modules achieve their desired aesthetics, withstand India’s harsh outdoor conditions, provide critical environmental sealing, and maintain structural and visual integrity over their extended service life. Don’t leave your product’s performance to chance—leverage the science of adhesion to build better, more reliable designs from the ground up.

Ready to apply this scientific approach to your next bonding challenge? Contact 3M’s technical experts today for a personalized consultation and explore our full range of advanced adhesive solutions